Quality

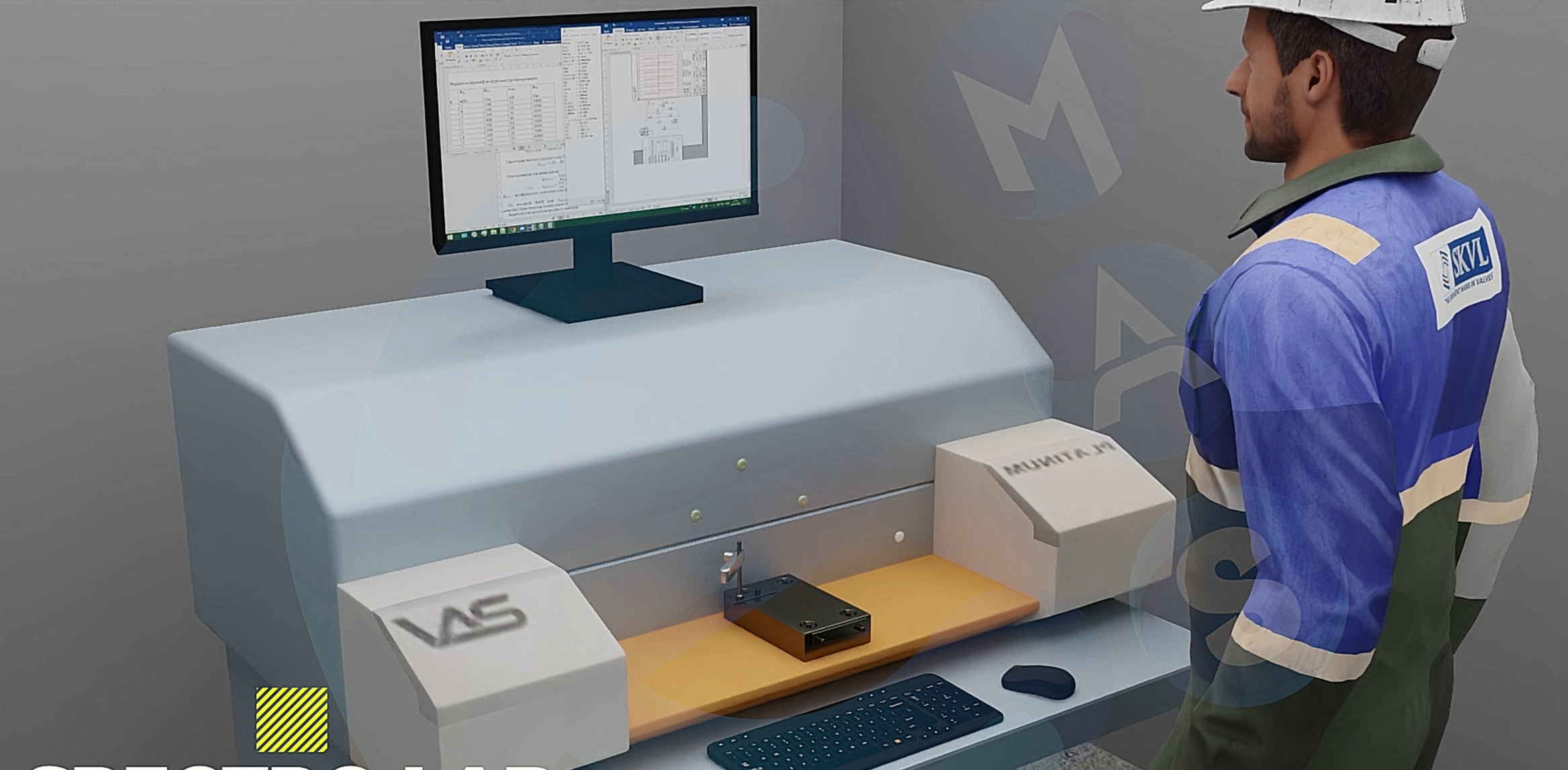

Material Composition: We verify the material composition with the help of the spectro analization, to ensure the composition of the material as per standards.

Dimensional Inspection: Measure critical dimensions such as the diameter,length and thread pitch to ensure it meets the specified requirements.

Visual Testing inspection: Check for any visible defects.

Rubber and Silicon O rings: Check hardness and compression of every batch.

Pressure Testing: Subject the valve to a pressure test to ensure it can withstand the specified operating pressure without leaking or failing.

Flow Rate Testing: Measure the flow rate of the valve to ensure it meets the specified requirements for water flow over a period of flows.

Endurance Testing: Operates the valves in different temperature and different temperature over time to know the life of the valve in real life senarios.

By doing these checks we ensure that our valves meet the required standards for performance, durability and reilability.

Manufacturing Process

17‑Step Manufacturing Process

Casting: Copper & Zinc

Peeling Brass Rod

Visual & Dimensional Inspection

Forging

Dimensional Inspection

Spectroscope Analysis

Tooling & Machining

Dimensional Inspection

Visual Inspection

Cleaning

Assembly

Movement Testing

Dimensional Inspection

Leakage Testing

Visual & Manual Inspection

Packaging

Workflow Completed